- AppSheet

- :

- AppSheet Forum

- :

- AppSheet Q&A

- :

- Stock management in multiple locations

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

does anyone knows how to make this?

whenever I add a new Product Variant, the bot / automation should create an inventory item copying some info of the product variant, then create a Inventory Level for all existing Locations (even if the location has 0 stock for this Product Variant on those Locations) and keep the inventory levels related to the inventory items and Locations.

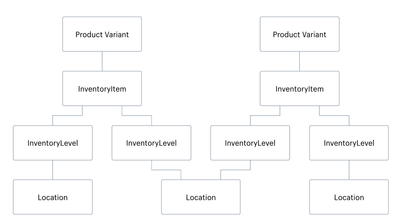

Product Variant: All product variants have a 1:1 relationship with their associated inventory item. Each product variant has one inventory item, and that inventory item belongs only to that product variant.

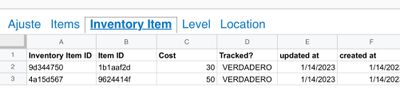

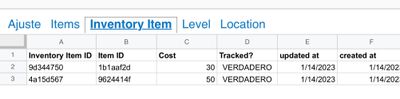

InventoryItem: Contains information about the physical product, such as its SKU, as the back-end information used for managing inventory. Inventory items are associated with one or many inventory levels. An inventory item will have an inventory level for each location where the item is stocked

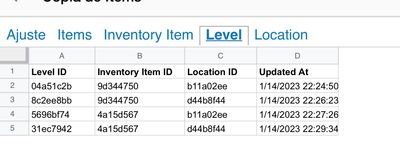

InventoryLevel: Represents the actual quantity of an item that is available. Inventory levels connect one inventory item to one location. Each inventory level holds the available quantity for its inventory item at the associated location.

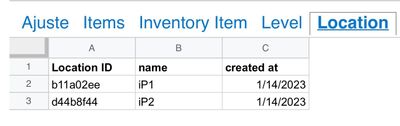

Location: Represents a geographical location of the point of sale.

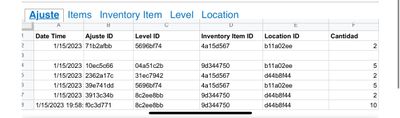

To show the current stock of the inventory level I use a Virtual column that calculates the current stock:

SUM(SELECT(Order[Quantity],

AND( [Location ID]= [_THISROW].[Location ID], [Inventory Item ID]= [_THISROW].[Inventory Item ID] )))

Thank you very much to all the google appsheet comunity!!

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

To copy a product variant to an inventoryItem is straight forward.

To create inventoryLevels from the newly created inventoryItem requires a modified set of steps described here. Here your enumlist will be a list of all the locations.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I am not sure how much of this you have already created but to do

@allanfocker wrote:

Meaning that records on inventory level and inventory items should be deleted when product variant is deleted as well.

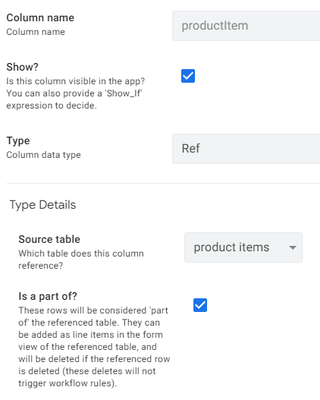

you need to set is a part of flag (reference doc) on edited: inventoryItem productItem -> productVariant and inventoryLevel -> inventoryItem productItem

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thank you for your response, im stuck at the part of triggering this when a new product variant is added by user:

- Step 1 Copy the id variant, cost and tracked? columns from the product variant to a new row in the inventory item table

- Step 2 add into the inventory level table a row for every location referenced to inventory item

Currently works like this:

ajuste means adjustment

but lacks of automation, if i add a new product variant it wont add by it self the inventory levels for each existing location

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

To copy a product variant to an inventoryItem is straight forward.

To create inventoryLevels from the newly created inventoryItem requires a modified set of steps described here. Here your enumlist will be a list of all the locations.

-

!

1 -

Account

1,687 -

App Management

3,143 -

AppSheet

1 -

Automation

10,387 -

Bug

1,001 -

Data

9,733 -

Errors

5,781 -

Expressions

11,854 -

General Miscellaneous

1 -

Google Cloud Deploy

1 -

image and text

1 -

Integrations

1,629 -

Intelligence

586 -

Introductions

87 -

Other

2,939 -

Photos

1 -

Resources

545 -

Security

837 -

Templates

1,319 -

Users

1,565 -

UX

9,141

- « Previous

- Next »

| User | Count |

|---|---|

| 37 | |

| 30 | |

| 29 | |

| 22 | |

| 18 |

Twitter

Twitter